Collated data from NHTSA keyword search 2013-2019 that identify carbon monoxide incidents/complaints with various automobile makes and suspected defects.

Residential Dwelling Requirements (State_CO_Regulations_Summation_July_2016)

Make sure your carbon monoxide engineering expert complies “below taken from Early v. Toyota Motor Corp., 2007 U.S. Dist. LEXIS 36011 (E.D. Ky., May 16, 2007).

First, a court must determine whether the expert is qualified to offer opinions in a particular subject area. Once the court determines that an expert is qualified to offer opinions in a particular subject area, it must consider whether the expert’s opinion is reliable. In Daubert, HN2the Supreme Court suggested that the issue of reliability turns on whether an expert’s reasoning or methodology is scientifically valid [**6] or whether that reasoning or methodology can be properly applied to the facts in issue. In considering an expert’s reliability, trial court’s should consider the following:

Daubert, 509 U.S. 593-594. 2 In making reliability determinations, the court’s inquiry must be specific to the particular issues in each case. Kumho Tire Company, 526 U.S. at 156. [*637] In other words, a trial court must decide whether an expert has sufficient specialized knowledge to assist the jury in deciding the issues in the case. Accordingly, an expert’s conclusions regarding causation must have a basis in established fact and cannot be premised on subjective beliefs or mere suppositions. McLean v 988011 Ontario, Ltd., 224 F.3d 797, 800-801 (6th Cir. 2000).

Carbon Monoxide poisoning and deaths occurs due to portable generator exhaust gas emissions where:

Technology advancements in carbon monoxide sensor technology could be used to totally prevent carbon mon

oxide poisoning by triggering interlock and shut-off circuitry in most situations. Most often than not, this could be achieved using economically and practically implemented solutions.

Carbon Monoxide Poisoning often occurs in cases of vehicular and transportation scenarios that include:

“Gathering Engineering Evidence for Carbon Monoxide Toxicity Cases”, Medicine, Science and the Law, British Academy for Forensic Sciences, 2015 (PDF)

More often than not, CO causation can be visually identified due to obvious tell tale signs such as cracked flue vents or physical soot formation and deposits. Investigation may be required to identify misdirected exhaust or natural air diffusion that transports contaminants into the occupant space.

Compliance and Verification?

Problematic carbon monoxide sources include portable generators, boilers, furnaces and other combustible burning appliances. Compliance with CO product warning/emissions labeling and state EPA exhaust certification should be verified. Compliance and verification of the following should also be inspected:

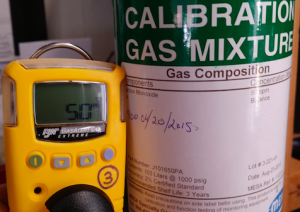

Engineering forensic analysis of a carbon monoxide case comprises of well designed CO measurements and/or modeling.

This becomes pivotal in non-fatal and/or chronic CO exposure cases where victims suffer neurological damage. Quantifying CO exposure such as “how much CO?”, “what concentration?” and “length of exposure?” are crucial elements in “closing the loop” with physiological evidence.

Was the source CO concentration quantified?

Were CO air free measurement undertaken (?) in order to determine if suspect appliance(s) comply with ANSI carbon monoxide emission limits?

What were the resultant ambient CO concentration levels? (and for what period of time?)

Obtaining ambient field measurements of CO concentrations is more complex than analyzing air free exhaust gas due to the non restrictive air dynamics one finds in a environment such as a home. Walking with a CO meter in hand is unacceptable. The act of walking with the monitor creates microplumes that distorts CO data readings that would be a point of contention.

Event reconstruction forensics of ambient CO concentration is undertaken using EPA accredited software and modeling methods to estimate ambient measurements and CO exposure magnitudes:

Why didn’t the CO detector alarm?

CO laboratory measurements can verify correct operation and compliance with UL2034 “Single and Multiple Station Carbon Monoxide Alarms”. If it is deemed that CO detector alarm and sensor verification of compliance is required, then CO detectors should be tested in a controlled laboratory environment.

Technology advancements in carbon monoxide sensor technology could be used to totally prevent carbon monoxide poisoning by triggering interlock and shut-off circuitry in most situations. Most often than not, this could be achieved using economically and practically implemented solutions.